SEE Laser Testing

Laser testing is a crucial method used in radiation hardness assurance (RHA) to evaluate the susceptibility of electronic components and systems to single event effects (SEEs) induced by ionizing radiation. It complements traditional heavy ion testing methods by providing a versatile and efficient means of simulating radiation-induced events in a controlled laboratory environment.

How Laser Testing Works

Laser testing involves the use of high-energy laser pulses to replicate the effects of ionizing radiation on electronic devices. These laser pulses generate localized charge carriers within semiconductor materials, simulating the ionization events caused by energetic particles in space or other radiation-rich environments.

The process typically involves the following steps:

- Part Preparation: Before testing, electronic components are prepared for laser irradiation. This preparation often involves opening the components from the bottom side, similar to heavy ion testing, and ensuring that they are properly mounted and positioned for irradiation.

- Pulse Generation: A high-energy laser system generates short pulses of coherent light with precise energy and intensity parameters.

- Target Irradiation: The laser pulses are directed onto the target electronic device or component, inducing transient electrical effects similar to those caused by ionizing radiation.

- Response Analysis: The response of the device to the laser-induced events is measured and analyzed to assess its susceptibility to single event effects, such as single event upset (SEU), single event latch-up (SEL), and single event transient (SET).

Benefits of Laser Testing

- Revolutionary SEE Testing: Laser testing revolutionizes Single-Event Effect (SEE) testing by leveraging pulsed laser sources to induce transient electrical events in electronic components, providing a precise and controlled method for evaluating device reliability.

- Enhanced Spatial Resolution: Laser testing offers unparalleled spatial resolution and SEE mapping capabilities that are not achievable with traditional heavy ion testing methods, allowing for precise localization of radiation-induced events within electronic circuits.

- Monitoring Diverse Events: Laser testing enables the monitoring of both destructive and non-destructive single event effects, including Single Event Latch-up (SEL), Single Event Transient (SET), Single Event Upset (SEU), among others, providing comprehensive insights into device behavior under radiation exposure.

- Accessibility and Rapid Results: Laser testing offers high accessibility and immediate results, facilitating faster development cycles and enabling swift assessment of device reliability and performance in radiation-rich environments.

- Precise Analysis: Laser testing allows for precise analysis of the most vulnerable regions within electronic circuits, enabling targeted mitigation strategies and validation of radiation-hardness designs.

- Cost-Effectiveness: Laser testing offers reduced testing costs compared to traditional methods such as heavy ion testing, making it an economical choice for evaluating device reliability and radiation resilience.

>> Leporello Laser Testing

Applications of Laser Testing

- Part Screening: Laser testing is used for screening both radiation-hardened and Commercial Off-The-Shelf (COTS) components to assess their susceptibility to single event effects and ensure reliability in radiation-rich environments.

- Accurate Event Localization: Laser testing enables accurate localization of radiation-induced events within electronic circuits, allowing for targeted analysis and mitigation of vulnerabilities.

- Identification of Sensitive Nodes: Laser testing helps identify sensitive nodes within electronic circuits that are prone to single event effects, guiding design improvements and reliability enhancements.

- Reliability Screening: Laser testing is utilized for reliability screening of electronic components and systems to ensure their robustness in harsh radiation environments.

- Verification of Radiation-Hardened Circuits: Laser testing validates the effectiveness of radiation-hardened circuit designs by subjecting them to controlled radiation exposure and assessing their performance.

- Designing Radiation-Hardened Electronics: Laser testing aids in the design and development of radiation-hardened electronics by providing insights into the susceptibility of components to single event effects and guiding mitigation strategies.

- Mechanism Studies: Laser testing facilitates mechanism studies to understand the underlying physics of single event effects and their impact on electronic devices.

- Model Validation and Calibration: Laser testing is used to validate and calibrate models for predicting single event effects, ensuring accuracy in radiation hardness assurance assessments.

- Lot-to-Lot Variation Testing: Laser testing enables testing for lot-to-lot variations in electronic components, ensuring consistency and reliability across production batches.

- Memory Mapping: Laser testing is employed for mapping memory to identify vulnerable regions and assess the reliability of memory devices under radiation exposure.

- Fault Injection Tests: Laser testing is utilized for fault injection tests to simulate single event effects and assess the robustness of electronic systems against transient radiation-induced faults.

Complementarity to Heavy Ion Testing

Laser testing complements traditional heavy ion testing methods in several ways:

- Precision Control: Laser testing allows for precise control over the energy, intensity, and spatial distribution of radiation-induced events, enabling more accurate characterization of device responses compared to heavy ion testing.

- Safety: Laser testing poses minimal safety risks to personnel and the environment compared to heavy ion or proton testing, which requires specialized facilities and safety precautions due to the use of particle accelerators.

- Speed and Efficiency: Laser testing offers a faster and more efficient testing process compared to heavy ion testing, enabling rapid assessment of device reliability and performance in radiation-rich environments.

- Versatility: Laser testing can be easily tailored to simulate various radiation environments, making it a versatile tool for assessing device reliability across different industries and applications.

Our SEE Laser Testing Services

At Seibersdorf Laboratories, we offer comprehensive SEE laser testing services tailored to meet your specific requirements. Our team of experts utilizes cutting-edge laser technology and sophisticated test setups to ensure accurate and reliable results. Whether you need to assess the susceptibility of integrated circuits, memories, or other electronic components to single event effects, our SEE laser testing capabilities can help you make informed decisions about the reliability of your devices.

Why Choose Seibersdorf Laboratories for SEE Laser Testing?

- Expertise: Our team of experienced professionals has extensive knowledge and expertise in radiation testing and SEE laser testing methodologies, ensuring the highest quality of service.

- State-of-the-Art Facilities: We maintain state-of-the-art testing facilities equipped with advanced laser systems and instrumentation to provide accurate and reliable test results.

- Compliance: Our SEE laser testing services comply with relevant industry standards and guidelines, ensuring that your testing needs are met with the highest level of quality and reliability.

- Customization: We work closely with our clients to understand their unique testing requirements and tailor our SEE laser testing services to meet their specific needs and objectives.

Conclusion

SEE laser testing is a vital tool for assessing the radiation tolerance of electronic components and systems in various applications. At Seibersdorf Laboratories, we offer comprehensive SEE laser testing services to help you evaluate the reliability of your devices and ensure their performance in radiation environments. Contact us today to learn more about how our SEE laser testing capabilities can support your testing needs.

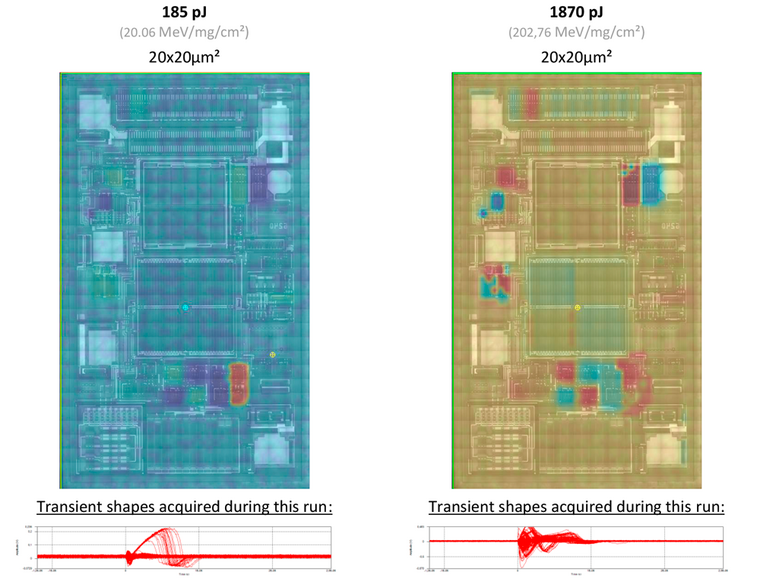

SEE laser testing allows to localize the sensitive regions on the chip. The example shows single event transients (SET) on a commercial operational amplifier (LTC6240). Both the position and the waveform of the transients are monitored in real-time. The tunable laser source allows to realize different LETs on the device under test.

![[Translate to English:] [Translate to English:]](/fileadmin/uploads/intranet/images/header/ld/header-strahlungsfestigkeit.jpg)