Total Ionizing Dose Testing

Total Ionizing Dose (TID) testing is a crucial component of Radiation Hardness Assurance (RHA) for electronic components intended for use in radiation-intensive environments such as space missions, nuclear facilities, and medical applications. At Seibersdorf Laboratories, we offer comprehensive TID testing services to ensure the reliability and performance of components under the influence of ionizing radiation.

TEC Laboratory

The TEC Laboratory is Seibersdorf Laboratories’ newest Co-60 test facility entirely dedicated to total ionizing dose (TID) testing of electronic components and systems. It is equipped with state-of-the-art infrastructure to perform TID testing in accordance with industry standards. Accredited to EN ISO/IEC 17025, our laboratory provides 24/7 testing services for electronic components, devices, systems, and materials. The facility features a spacious exposure room with a wide uniform field size, enabling accurate TID testing in accordance with ESCC-22900, MIL-STD-750, and ECSS standards.

>> Video TEC

Key Features of our TID Exposure Facility

- High-activity Cobalt-60 irradiation source with a dose rate range of 0.3 Gy/h to 50 Gy/h.

- Pneumatic system for source movement and precise exposure control.

- Shielding container and collimator for radiation safety and accuracy.

- Automatic data logging of source conditions, facility access, and environmental parameters.

- High-quality multichannel dosimeter system for accurate dose measurement and monitoring.

TID Test Standards

We adhere to stringent test standards set forth by ESCC, ECSS, and MIL-STD to ensure the reliability and integrity of our TID testing procedures. These standards, including ESCC Basic Specification No. 22900, ECSS-Q-ST-60-15, MIL-STD-883 Test Method 1019.9, and MIL-STD-750 TM1019.5, define the requirements for testing semiconductor devices for total ionizing dose effects.

At Seibersdorf Laboratories, we are committed to excellence in TID testing, providing reliable and accurate assessments to support the development of radiation-hardened electronic systems for critical applications. Trust us to safeguard the performance and reliability of your components in radiation-rich environments.

TID Testing Results

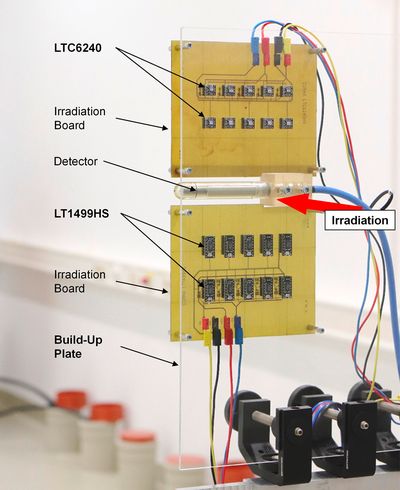

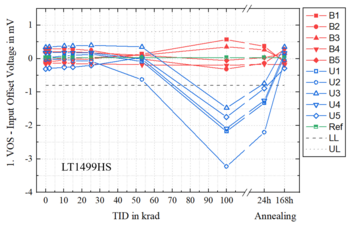

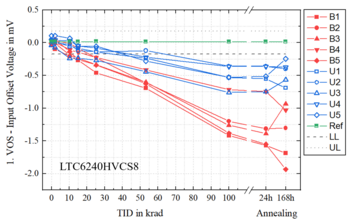

As an illustration of our TID testing capabilities, we present exemplary TID testing from two two operational amplifiers, tested within the ESA CORHA study for radiation screening of commercial off-the-shelf components for the space industry [REF]. The components underwent rigorous testing in our TEC Laboratory Seibersdorf to assess its performance under ionizing radiation.

Co-60 TID exposure set-up of COTS operational amplifiers LTC6240HVCS8 (upper PCB) and LT1499HS (lower PCB). Within the ESA CORHA project, both devices were irradiated in six exposure steps to a total dose of 100 krad(SI) in the TEC Laboratory Seibersdorf.

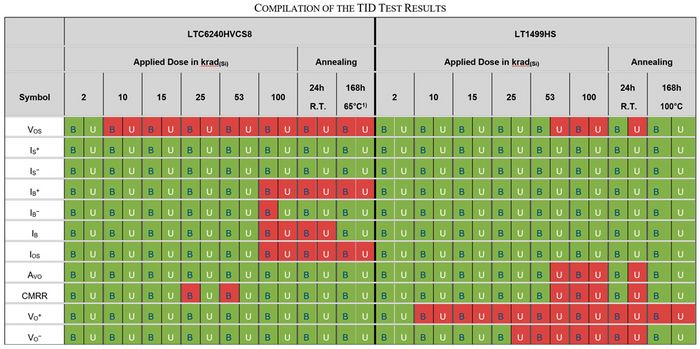

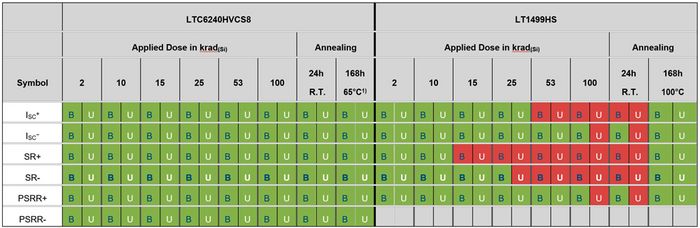

A green cell color indicates that all biased (B) and unbiased (U) devices are within the specification limits, otherwise the cell is marked red.

1) 168 hours annealing is performed at 65°C in order not to exceed the maximum guaranteed operating temperature of 70°C specified in the device's datasheet.

Degradation of the input offset voltage VOS of the LTC5240HVCS8 (left) and LT1499HS (right) COTS operational amplifiers as a function of dose and after 24h and 168h annealing. Biased devices in red, unbiased devices in blue, and the non-irradiated reference device in green. Lower (LL) and upper (UL) limits as specified in the test plan in dashed and dotted lines, accordingly.

The CORHA Project

The LTC6240 was one out of 12 components that were radiation tested as part of the CORHA project, coordinated by Seibersdorf Laboratories in collaboration with the University of Padova, Italy. The CORHA project aimed to assess the radiation hardness of commercial off-the-shelf (COTS) components and develop a specialized RHA approach tailored for these components. This endeavor underscores our commitment to advancing the reliability of electronic systems in space and other radiation-rich environments. For more information on the CORHA project please consult the references below or reach out to us.

References

- M. Wind et al., "Testing of COTS Multiplexer in the Framework of the ESA CORHA Study," 2021 21th European Conference on Radiation and Its Effects on Components and Systems (RADECS), Vienna, Austria, 2021, pp. 1-7, doi: 10.1109/RADECS53308.2021.9954531.

- C. Tscherne et al., "Testing of COTS Operational Amplifier in the Framework of the ESA CORHA Study," 2020 20th European Conference on Radiation and Its Effects on Components and Systems (RADECS), Toulouse, France, 2020, pp. 1-7, doi: 10.1109/RADECS50773.2020.9857692.

- M. Wind et al., "SEE Testing of COTS Microcontroller and Operational Amplifier in the Framework of the ESA CORHA Study," 2022 22nd European Conference on Radiation and Its Effects on Components and Systems (RADECS), Venice, Italy, 2022, pp. 1-8, doi: 10.1109/RADECS55911.2022.10412391.

Our TID Testing Services

- Total Ionizing Dose (TID) testing services for electronic components and materials conducted in accordance with industry standards (ESCC, ECSS, MIL-STD)

- TID testing on component, board or (sub-)system level

- State-of-the-art Total Ionizing Dose Exposure Facility accredited with EN ISO/IEC 17025 for traceable and accurate radiation exposure

- Extensive experience in TID testing, including participation in projects for the European Space Agency (ESA) and the European space industry.

- Expertise in assessing radiation hardness of commercial off-the-shelf (COTS) components.

- Detailed reporting and analysis of TID testing results to inform decision-making.

- Dedicated to providing exceptional service and support to meet client needs.